NEWSLETTER

03/2025

Cement industry advances net-zero with carbon capture projects

Large-scale and pilot projects explore absorption, oxyfuel, cryogenic and membrane methods

The cement industry is making progress in developing the first net-zero production lines. Large-scale projects promise significant knowledge gains from operating carbon capture plants at an industrial level, while additional capture technologies are being developed on a pilot scale to expand the available options. Different carbon capture technologies exhibit varying degrees of maturity.

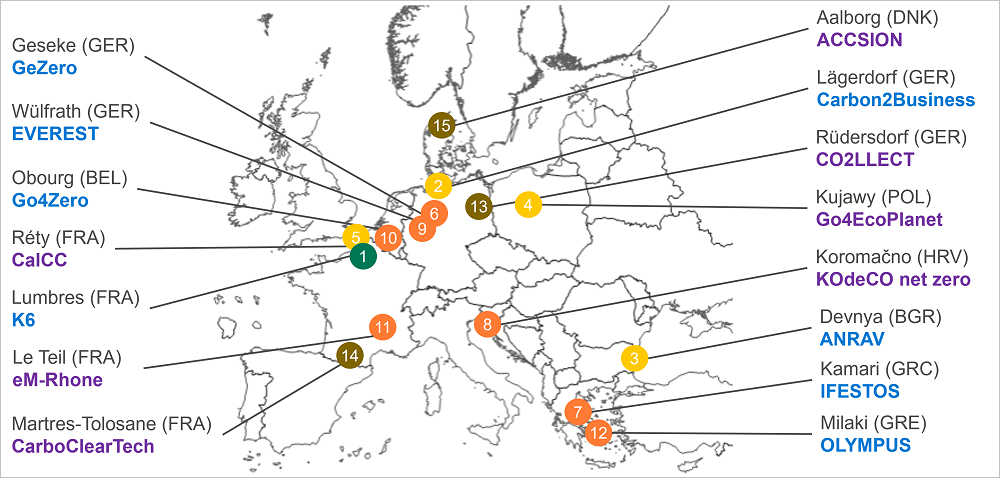

In the cement industry, early mover projects are focusing on various forms of mature amine scrubbing, absorptive-cryogenic capture and oxyfuel combustion. These technologies are already in operation, under construction, or in the planning stage for several projects. Many of these planned projects are large-scale, and many European projects have secured funding through the EU Innovation Fund. So far, the fund has awarded eight oxyfuel kilns and seven absorptive-cryogenic capture plants to the lime and cement industries (Figure 1). Further technologies, such as adsorption using metal-organic frameworks (MOFs), capture with hot potassium carbonate, cryogenic desublimation and membrane separation, are progressing at a pilot level and solving key issues that will enable large-scale applications.

Absorption capture via amines

The world's first large-scale carbon capture plant in the cement industry began operating in Norway in 2025. As part of the 'Longship' project, the first tons of CO₂ were recently captured using an amine scrubber at the Brevik cement plant, before being shipped to the 'Northern Lights' CO₂ storage site. The most notable feature of this project is the use of waste heat to power the reboiler, enabling 50 % of CO₂ emissions to be captured without the need for an additional steam generator.

Despite the long experience available in utilising absorption technologies, ongoing advancements persist in enhancing energetic performance, ensuring solvent stability, and facilitating heat integration through the use of heat pumps. However, operational costs exceed 100 €/t CO₂, and the strict CO₂ specifications for Northern Lights remain challenging. However, the carbon-neutral EvoZero cement produced in Brevik has already been sold in advance, proving to be a success.

Oxyfuel technology

Oxyfuel technology has the potential to reduce costs in the future compared with post-combustion technology. Nevertheless, incorporating the process into the clinker production line requires alterations to the equipment, giving rise to technical complexities, particularly with regard to precisely controlling false air. Testing single units at prototype level has advanced the technology. The first industrial-scale demonstration plant (with a capacity of 450 tons of clinker per day) is to be operated by the CI4C consortium in Mergelstetten, with commissioning expected in Q3/2025. It is anticipated that the project will generate considerable knowledge in the field of oxyfuel kiln operation. This advancement will lay the foundation for the large-scale implementation of planned projects commencing in 2030.

Moreover, demonstration plants incorporating oxyfuel calciners (OxyCal) and partial oxyfuel concepts have been established in Bulgaria (ANRAV) and China (China United Cement Qingzhou Plant). The objective of this work is to reduce the risk of large-scale applications planned until 2028.

Adsorptive capture

Adsorptive capture processes, such as temperature swing adsorption (TSA) and pressure swing adsorption (PSA), rely heavily on improvements to their absorbent materials in the same way that adsorption processes depend on solvents. The use of MOFs has been shown to markedly reduce energy demand. The long-term durability and economic viability of the process are determined through pilot-scale testing, as demonstrated by Svante's work on TSA and Nuada's work on PSA. However, the promising characteristics of MOF absorbents have thus far been offset by elaborate production processes involving high costs and limited market potential. However, initiatives such as Svante’s Gigafactory for absorbents are addressing this challenge. The company reports that the absorbents can now be produced more easily and cheaply.

Cryogenic capture

Combining proven adsorption technology with CO₂ liquefaction brings together the advantages of both technologies. The adsorption process enriches the CO₂ without the need for very high concentrations, whereas the cryogenic unit operates more efficiently at elevated levels. Despite being based on mature single components, this concept has only been applied on a small scale. Large-scale applications are currently in the detailed engineering phase and are scheduled to commence operations by 2028.

Alternate methodologies employ the desublimation of CO₂, whereby the gas is separated into a solid, which is then melted for transportation. There is potential for energy efficiency gains through reducing compression requirements. This could benefit from the maturity of existing cryogenic processes; however, desublimation technology is still in its early stages.

Membrane separation

Significant progress has been made in the field of membrane carbon capture in the cement industry, with the technology reaching the early demonstration stage. This development is accompanied by a strategic focus on achieving progressive scale-up, with the aim of expanding the technology's application and impact more widely. Earlier trials have demonstrated the technology's feasibility. Subsequent advancements are aimed at enhancing the materials' selectivity for CO₂ and their resistance to impurities.

In an ECRA online seminar, representatives from major carbon capture projects and providers of capture technology will present updates on this topic alongside experts on carbon capture legislation and funding: